Showing posts with label light box. Show all posts

Showing posts with label light box. Show all posts

Saturday, October 14, 2017

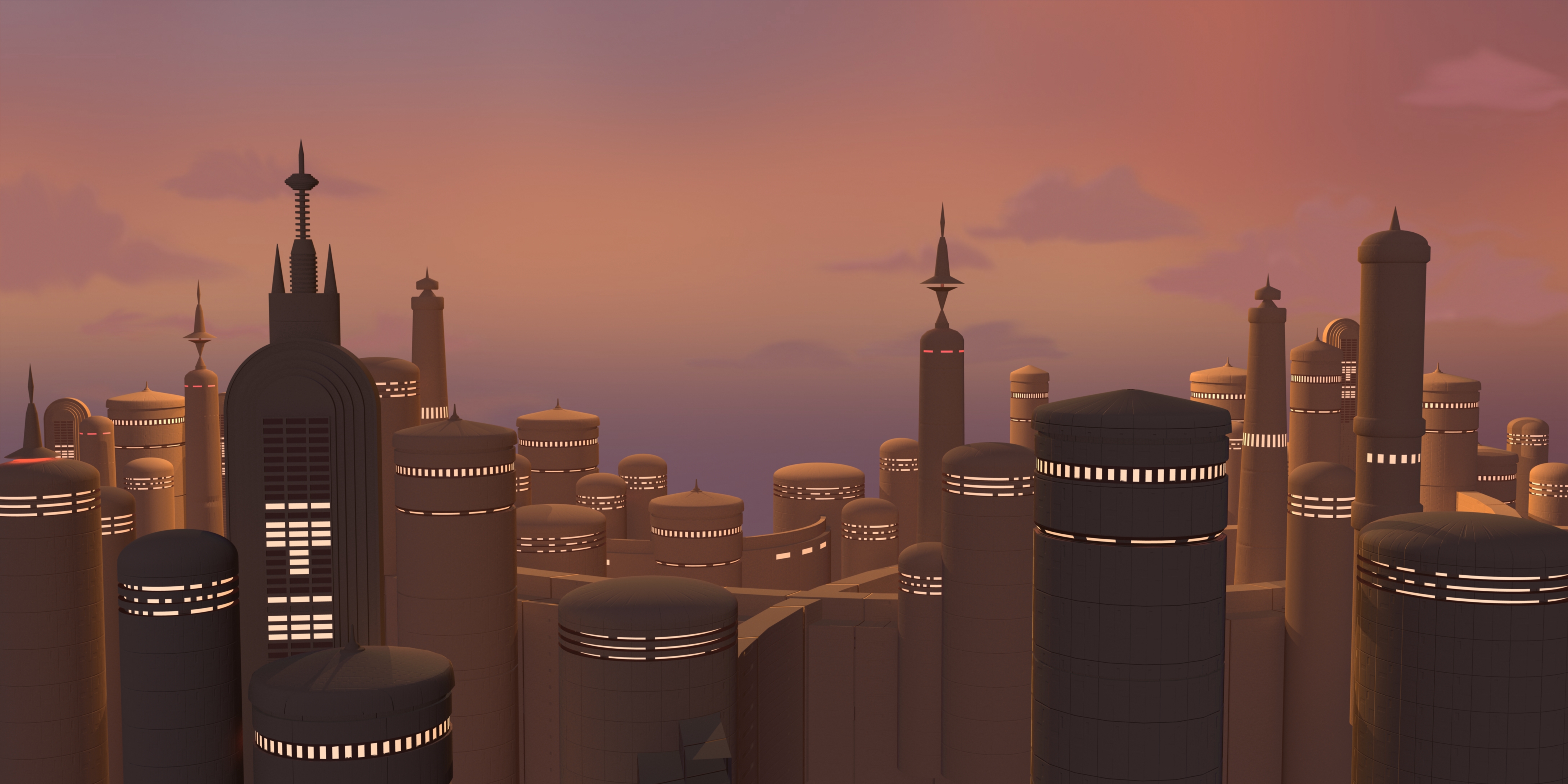

Tiny Bandai Millennium Falcon Build II

Using 3d software to create the background image that will be incoprporated in the Bespin diorama as a lightbox. Will act as a backdrop and lightsource for the millennium falcon sitting on it's platform.

Labels:

led,

light box,

millennium falcon,

scale model,

Star Wars

Tuesday, April 28, 2015

Leather Watch Case With Lighting Part 4: Finished

It took me about a week in total, mostly evenings, to finish this project. I'm very pleased with it I must say. Could it have been done better? Yes, especially dealing with the faux leather around corners, next time I will have to think about how to do that better. There were still some small jobs to do after it was basically done. For instance, I had to make a cover to hide the battery that powers the lighting. The acrylic sheet had a lot of scratches, which I buffed out mostly at the cost of it being no more shiny. The underside has some velt feet to keep the leather from being scratched. The closing mechanism needed some more adjusting cause I could barely open it. All in all quite some work but it was worth it. Now I can start collecting some watches! :)

Sunday, February 22, 2015

Leather Watch Case With Lighting Part 3

This is another fun part, making a latch for the case. Here's some photos of the bottom part of the latch, I forgot to make photos of the top part because I was so enthousiastic about making it :)

It's a brass plate that's cut in a way so I can fold it along the case edge. Holes are drilled for screws and the brass rod. This brass rod is used to hold a triangular wire that will clasp to the bottom part of the case. The rod is soldered to the brass plate but it also extends into the case wall to give it extra strength.

Then the parts are screwed into place and I filed the bottom rod part of the latch so the triangular piece will slide and hold easily. Very pleased with this result, it's not the cleanest looking thing but I like the handmade quality it has. Next post will show the end result of the watch case!

| |||

| Fabricating the bottom part of the latch |

It's a brass plate that's cut in a way so I can fold it along the case edge. Holes are drilled for screws and the brass rod. This brass rod is used to hold a triangular wire that will clasp to the bottom part of the case. The rod is soldered to the brass plate but it also extends into the case wall to give it extra strength.

Then the parts are screwed into place and I filed the bottom rod part of the latch so the triangular piece will slide and hold easily. Very pleased with this result, it's not the cleanest looking thing but I like the handmade quality it has. Next post will show the end result of the watch case!

| |

| The finished latch on the case |

Thursday, February 19, 2015

Leather Watch Case With Lighting Part 2

As soon as the lid was covered in leather I stuck a led strip on the inside and saw how it looked, it's perfect, it highlights the watch and the led strip remains hidden from view.

I continued with applying leather to the case and cut a piece of acryllic glass to fit the window. I will also need to maken some dividers in the case to give the watches each it's indivual place that will hold it in place also. The watches will be supported each with a piece of foam that I need to shape like a wrist. Next post I'll be attaching the lid to the case with hinges and we can start filling the case with dividers.

I continued with applying leather to the case and cut a piece of acryllic glass to fit the window. I will also need to maken some dividers in the case to give the watches each it's indivual place that will hold it in place also. The watches will be supported each with a piece of foam that I need to shape like a wrist. Next post I'll be attaching the lid to the case with hinges and we can start filling the case with dividers.

|

| Trying out the lighting |

|

| Lid has glass and lighting installed |

|

| Almost done covering the case in leather |

Wednesday, February 18, 2015

Leather Watch Case With Lighting Part 1

I've recently got bitten by the watch bug :) Haven't worn a watch since my childhood but after I got me a Casio watch for work I got obesessed with them and ordered some unusual ones on Ebay. Needless to say I need to get a home for my future watch collection. What better way then to make a watch case yourself.

I used a wine gift box, it's about a foot long, 4 inches high. It has a piece of wood that slides to close the box. I glued this in place cause I need the top to be closed. I then cut the box length wise to make the bottom part of the case, about 2 inches high. I then cut the remaining part again to get a thin top. Then a window was cut out through which we will be able to see the watches. Faux leather was then glued to the lid to create a nice look that is associated with watches and jewelry. On the inside of the lid there's just enough room for a strip of led lights, which I will show in the next post.

I used a wine gift box, it's about a foot long, 4 inches high. It has a piece of wood that slides to close the box. I glued this in place cause I need the top to be closed. I then cut the box length wise to make the bottom part of the case, about 2 inches high. I then cut the remaining part again to get a thin top. Then a window was cut out through which we will be able to see the watches. Faux leather was then glued to the lid to create a nice look that is associated with watches and jewelry. On the inside of the lid there's just enough room for a strip of led lights, which I will show in the next post.

|

| Wine box cut in pieces |

|

| Case and lid with window |

|

| Starting to glue leather to lid |

Wednesday, February 11, 2015

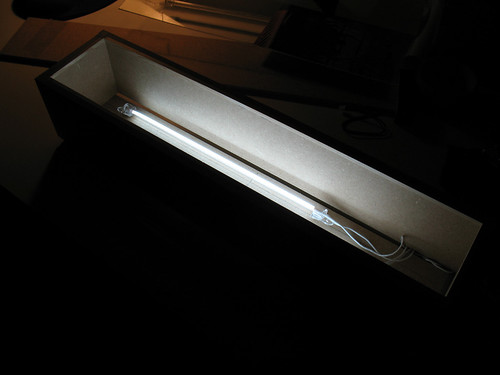

Custom Light Box

Made a light box measuring 17 by 11 inches using MDF wood, acryllic glass and CCFL tube lights. Light box can be hung on a wall or stood on a shelf or table. Powered by a 12 volt power supply and has a dimmer to control light level.

Labels:

electronics,

handmade,

led,

light box,

photography,

plexi glass,

wood

Tuesday, September 9, 2014

Friday, May 2, 2014

Landscape Light Box Part 3

Here's an update on the light box. I have started painting the box and all the electronics and CCFL tubes are test fitted with screws in place. There are two transformers that convert 12 volts to 300 volts. Everything fits nicely in the box. Wires from teh converter join to a wire block, from there a wire runs out of of the box to a 12 volt adapter. Once painting is done all I need is two sheets of clear acryllic glass and a photo print.

Sunday, April 13, 2014

Landscape Light Box Part 2

I've installed a small strip of wood to form an inner frame that will hold the clear plastic and print. Put primer on it which will allow me to see if I need to sand the front some more to make the strip and box flush. In the meantime I am glueing pieces of wood on the backside which is a piece that will hold the electronics and lights. The pieces of wood will allow me to screw the lights down to the back. So next time I will probably have the lights mounted on the back, after which I can drill holes for ventilation and hanging.

Friday, April 11, 2014

Landscape Light Box Part 1

I've been wanting to do this one for a while. A wide light box for a landscape photo. This one will be about 20 by 4 inches, 50 by 10 centimeters. By 10 cm deep because this will allow the box to stay on a surface if not hung on a wall and not fall over if it was less deep, thinner.

The box is made of MDF and glued, on the front side I glued small strips of wood that will serve as a frame to hold the picture and the plexiglas/acryllic glass, clear plastic.

What you see here is a test of how much light is generated by 3 CCFL's in this box and how I should arrange them. This is critical cause I also need to fit the power converters inside the box without blocking the light. The CCFL's are like thin tube lights (used in laptops and pc case modding and cars), they work on about 300 volts which are generated by a converter (a small box you get with the lights), input is 12 volts. Currently I'm using a 3 amp adapter to power these, I'm not sure how much the CCFL's can consume, but I see the difference from when I was using a 1 amp adapter. Way more light now. It actually lights up the room. May also try some LED strips in the future, they will probably use more power but won't be able to break (CCFL's will break if you drop them on the floor) and less heat, though CCFL's only get a little bit warm not ho

The box is made of MDF and glued, on the front side I glued small strips of wood that will serve as a frame to hold the picture and the plexiglas/acryllic glass, clear plastic.

What you see here is a test of how much light is generated by 3 CCFL's in this box and how I should arrange them. This is critical cause I also need to fit the power converters inside the box without blocking the light. The CCFL's are like thin tube lights (used in laptops and pc case modding and cars), they work on about 300 volts which are generated by a converter (a small box you get with the lights), input is 12 volts. Currently I'm using a 3 amp adapter to power these, I'm not sure how much the CCFL's can consume, but I see the difference from when I was using a 1 amp adapter. Way more light now. It actually lights up the room. May also try some LED strips in the future, they will probably use more power but won't be able to break (CCFL's will break if you drop them on the floor) and less heat, though CCFL's only get a little bit warm not ho

Saturday, December 22, 2012

Light Box

Subscribe to:

Posts (Atom)