I've finally started painting the boat. Allthough the deck is far from perfect, I decided it would be nicer to show the wood instead of hiding it with paint. So the deck and coamings are in clear varnish. Interior in grey. Before that I reinforced the cockpit bottom with some slats. Still working on some deck fittings, the cleats mainly. Plan is to launch the boat in two weeks!

Showing posts with label wood. Show all posts

Showing posts with label wood. Show all posts

Tuesday, May 9, 2017

Tuesday, April 18, 2017

DIY USB Anchor Light and Foldable Anchor Ball for a Small Boat

These little side projects are so much fun. By law you need a anchor light for the night and an anchor ball for the day, if you're using the anchor. But since my boat is just a small one it becomes very important to keep these things light and easy to stow away.

The anchor ball was quite easy to make. It's two black plastic holes with a slit cut to the center so they join together to make a ball. It folds flat and I've drilled holes in them to attach it to my flag pole.

The anchor light was a bit of a headache. First I looked around for quite a while to find a small but bright light in a housing that allows the light to be seen from 360 degrees around. I finally found such light on Ebay. It's powered with a standard USB connector, 5 volts. Which is handy cause I plan to take powerbanks and a solar charger with me on the boat.

I then cut a wooden rod in half and hollowed out the center for the power cable. Glued back together with epoxy and I have a mast with a small light at the end.

Now all I have to find out is where to put this mast on the boat. It should be removable and not permanently on the deck but I am also very hesitant to cut any holes in the deck. Need to think about that some more.

In the meantime check out the photo's of the build and the result.

The anchor ball was quite easy to make. It's two black plastic holes with a slit cut to the center so they join together to make a ball. It folds flat and I've drilled holes in them to attach it to my flag pole.

The anchor light was a bit of a headache. First I looked around for quite a while to find a small but bright light in a housing that allows the light to be seen from 360 degrees around. I finally found such light on Ebay. It's powered with a standard USB connector, 5 volts. Which is handy cause I plan to take powerbanks and a solar charger with me on the boat.

I then cut a wooden rod in half and hollowed out the center for the power cable. Glued back together with epoxy and I have a mast with a small light at the end.

Now all I have to find out is where to put this mast on the boat. It should be removable and not permanently on the deck but I am also very hesitant to cut any holes in the deck. Need to think about that some more.

In the meantime check out the photo's of the build and the result.

Thursday, March 30, 2017

Boat Update IV

I'm currently working on the coaming top, half round wood to protect the plywood. I totally underestimated this, it was really hard to bend this half inch piece of wood into the half round shape. Have lots of sanding and filling to do. A better and faster result was creating the anchor locker. I was so pleased when I actually made the hatch and it fitted perfectly. First I made the frame that covers the anchor locker deck frame and then made a piece of plywood to fit exactly into that frame, no small feat for an amateur like me. But I was cheering when it came out so nice. :)

I am already thinking about some kind of boat tent or cover for spending the night or protection from rain. I need to hold some cloth around the cockpit. And I would need some small hooks on the outside of the coaming to hold bungee cord that holds the cloth down. I couldn't find any of this sort of hardware anywhere. The closest I found were these small plastic J-hooks that are fitted on kayaks. So I decided to make my own out of aluminium. And then it got me thinking, what else can I make out of aluminium? So I made a deck vent, I don't really need one, but they look cool. I hammered a wooden pole into a sheet of aluminium and bent the edges in a vise. Drilled holes, sanded it and polished it. Looks like the real deal with a sort of homemade quality to it.

Soon I'll be starting to think about paint.

I am already thinking about some kind of boat tent or cover for spending the night or protection from rain. I need to hold some cloth around the cockpit. And I would need some small hooks on the outside of the coaming to hold bungee cord that holds the cloth down. I couldn't find any of this sort of hardware anywhere. The closest I found were these small plastic J-hooks that are fitted on kayaks. So I decided to make my own out of aluminium. And then it got me thinking, what else can I make out of aluminium? So I made a deck vent, I don't really need one, but they look cool. I hammered a wooden pole into a sheet of aluminium and bent the edges in a vise. Drilled holes, sanded it and polished it. Looks like the real deal with a sort of homemade quality to it.

Soon I'll be starting to think about paint.

Friday, December 23, 2016

Boat Update III

Winter is slowing the work on the boat a bit down. Epoxy doesn't set in low temperatures and the shed I'm using doesn't have heating. I did use a small electric heater but it's difficult to get the temperature up. As you can see I have all the main work done, side decks, fore deck and coaming. It's all a matter of fairing and filling up holes now. After that, paint and varnish :) In the second photo you can still see what the old boat used to be (the blue parts) and the new part set in between. Also, the outboard fitted to check it's low enough in the water. Can't wait to try her out.

Monday, October 10, 2016

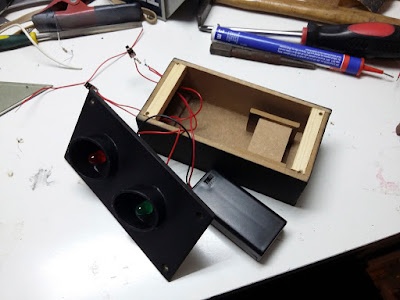

DIY Traffic Light For Kid's Bedroom

My cousin turned 8 years old and for his birthday he wanted something that could prevent his mom or anyone from entering his room without permission. Specifically, he wanted a stoplight. Naturally this appealed to my diy brain and I started working on it. I had no plan, I just wanted to make a wooden box with a red and green light, a batteryholder and a switch. Unfortunately I didn't have the right switch available so I had to mount separate switches for the red and green light. My cousin didn't bother with such technical details :)

Tuesday, October 4, 2016

Boat Update

The weather is getting colder here, autumn is upon is and thus limited time to work with epoxy. Managed to get a lot of work done, the outer hull is sealed and ready for paint, the interior needs one more coat of epoxy. After all the itchy sanding I finally had a chance to start working on the cockpit coaming, the edge around the cockpit and I like how it looks :)

Saturday, September 17, 2016

Boat Work Update

So I've cut my boat in half, added a new middle section, and now I'm working on making it one piece again. It's taking much more time than I expected, as usual. I made frames to support the new construction and recently started to add supports for the deck that will cover the front of the boat. The main part of this covered area will be used as flotation in case the boat get's swamped. Between the open cockpit and the flotation area is room for storage and you can see the opening for an access hatch I made.

The cockpit will be surrounded by a coaming, or a ledge, lean against when you sit. And I've made a new transom, a thicker one that can support the outboard engine. Still a lot to do, sanding, epoxy and fiberglass on the outside of the hull, paint, etc etc. And I will be making my own navigation lights. I hope to make some video's about those in the next couple of weeks. I'm making all of this up as I go, so tension is starting to build, I have no idea how this new boat will behave. For instance, it is quite narrow at 110 cm. It will be interesting to see how the length of the boat, 360 cm (12 feet) will behave with an outboard on top of the transom. Keeping my fingers crossed until launch day :)

The cockpit will be surrounded by a coaming, or a ledge, lean against when you sit. And I've made a new transom, a thicker one that can support the outboard engine. Still a lot to do, sanding, epoxy and fiberglass on the outside of the hull, paint, etc etc. And I will be making my own navigation lights. I hope to make some video's about those in the next couple of weeks. I'm making all of this up as I go, so tension is starting to build, I have no idea how this new boat will behave. For instance, it is quite narrow at 110 cm. It will be interesting to see how the length of the boat, 360 cm (12 feet) will behave with an outboard on top of the transom. Keeping my fingers crossed until launch day :)

Tuesday, April 12, 2016

Is Cutting a Boat in Half a Good Idea?

I built a small sailboat some years ago but it wasn't very usefeul. Cause it was too small for me. So I was thinking of building a new boat, from scratch. But then I thought, wait a minute, why not just make the boat I have a little bit bigger? There's all sorts of issues with that idea but nevertheless I'm going to try it against better judgment :) Here's the start of that project, after I had cut the boat in half, using stitch and glue technique to extend the boat by 4 feet. You will see in this blog in the coming months wether this was a good idea or not.

Friday, April 8, 2016

Friday, April 1, 2016

Friday, July 31, 2015

A Knife Handle

A friend asked me to put a wooden handle on this knife but keep the blade as it is (for sentimental reasons).

Friday, May 1, 2015

French Miner's Pocket Knife Part 4: Finished

Putting everything together is a lot of fun and also a bit nervewrecking as I have spent quite some hours on this one.

The spine is now flush with the handle and sanded smooth. Putting the blade on it requires putting tension on the spring (the spine) so that the blade can be locked open or closed. The last thing to do construction wise is to hammer the pins down. As it turned out I left the pins too long and bent the pins. Very disappointing but this is a lesson to remember for next time!

Now all there is left to do is coat the knife with linseed oil and it's done! The oil does a lot, it gives the grey-light color of the ashw ood a deep brown orange shine.

Later I sharpened the blade as well, it's pretty sharp. Really pleased with the result and will sure continue making some other french knives. Thanks for watching and enjoy the final shots of this knife.

The spine is now flush with the handle and sanded smooth. Putting the blade on it requires putting tension on the spring (the spine) so that the blade can be locked open or closed. The last thing to do construction wise is to hammer the pins down. As it turned out I left the pins too long and bent the pins. Very disappointing but this is a lesson to remember for next time!

Now all there is left to do is coat the knife with linseed oil and it's done! The oil does a lot, it gives the grey-light color of the ashw ood a deep brown orange shine.

Later I sharpened the blade as well, it's pretty sharp. Really pleased with the result and will sure continue making some other french knives. Thanks for watching and enjoy the final shots of this knife.

Labels:

epoxy,

folding knive,

handmade,

knife,

pocket knife,

project,

stainless,

wood

Thursday, April 30, 2015

French Miner's Pocket Knife Part 3

The wood has cured to the stainless steel parts, now I have to shape the wood. I used a grinding disk and hand viles. The grinding disk goes fast but it burns the wood so I use it to begin with and finish with the hand viles. At a certain point you get closer to the metal parts and the two start to merge together. I then drill holes for the metal pins and I can now begin to test fit it together to see how the overall shape will turn out. It's still too thick, more wood has to be removed for it to fit nice and comfortably in my hand.

When I get close to the final shape I wet the wood and grain will show up and protrude, you let it dry and sand off the fibers that are sticking out for a smoother finish. From now on I can just use sandpaper. I'm not worried about the top part, the spine of teh knife, it will probably need some viling to get the metal spine to sit flush with the handle pieces.

In the next part we will put everything together and finish the knife with a coat of linseed oil.

When I get close to the final shape I wet the wood and grain will show up and protrude, you let it dry and sand off the fibers that are sticking out for a smoother finish. From now on I can just use sandpaper. I'm not worried about the top part, the spine of teh knife, it will probably need some viling to get the metal spine to sit flush with the handle pieces.

In the next part we will put everything together and finish the knife with a coat of linseed oil.

Wednesday, April 29, 2015

French Miner's Pocket knife Part 2

The next step in creating the handle for the pocket knife was to glue the wood pieces to the metal pieces using epoxy. Then leave it alone for at least a day to fully cure.

In the meantime I etched a logo on the blade using electricity and an acid-salt solution. Nail polish is used to protect the steel and the logo was created by removing nail polish with a pencil or small scredriver.

I have seen knives that have the spine viled with decorative designs so I decided to give that a go as well. Carefully measuring the spine and putting marks where to vile. There's no "undoing" when you start this.

Next step will be to shape the handle and drill the holes for the steel rods that will keep everything together.

In the meantime I etched a logo on the blade using electricity and an acid-salt solution. Nail polish is used to protect the steel and the logo was created by removing nail polish with a pencil or small scredriver.

I have seen knives that have the spine viled with decorative designs so I decided to give that a go as well. Carefully measuring the spine and putting marks where to vile. There's no "undoing" when you start this.

Next step will be to shape the handle and drill the holes for the steel rods that will keep everything together.

Tuesday, April 28, 2015

French Miner's Pocket Knife Part 1

I have done pocket knives before, usually american types and some fake french, chinese made Laguiole knives. But while searching for other knife kits I happily stumbled upon a french website that offered knife kits from various french regions. I like the designs, they look pretty solid, something worthwhile spending your time on making it. So I ordered some and this is the first one I'm showing. It is called a "miner's knife", it's very simple but good quality 12c 27 steel. First, the choice of wood, I had some ash wood still lying around and it fits perfectly cause I don't want a showy knife with expensive wood, I want it to look like a tool. Here's some photos of all the pieces after I roughly shaped the wood to fit the handle.

Leather Watch Case With Lighting Part 4: Finished

It took me about a week in total, mostly evenings, to finish this project. I'm very pleased with it I must say. Could it have been done better? Yes, especially dealing with the faux leather around corners, next time I will have to think about how to do that better. There were still some small jobs to do after it was basically done. For instance, I had to make a cover to hide the battery that powers the lighting. The acrylic sheet had a lot of scratches, which I buffed out mostly at the cost of it being no more shiny. The underside has some velt feet to keep the leather from being scratched. The closing mechanism needed some more adjusting cause I could barely open it. All in all quite some work but it was worth it. Now I can start collecting some watches! :)

Sunday, February 22, 2015

Leather Watch Case With Lighting Part 3

This is another fun part, making a latch for the case. Here's some photos of the bottom part of the latch, I forgot to make photos of the top part because I was so enthousiastic about making it :)

It's a brass plate that's cut in a way so I can fold it along the case edge. Holes are drilled for screws and the brass rod. This brass rod is used to hold a triangular wire that will clasp to the bottom part of the case. The rod is soldered to the brass plate but it also extends into the case wall to give it extra strength.

Then the parts are screwed into place and I filed the bottom rod part of the latch so the triangular piece will slide and hold easily. Very pleased with this result, it's not the cleanest looking thing but I like the handmade quality it has. Next post will show the end result of the watch case!

| |||

| Fabricating the bottom part of the latch |

It's a brass plate that's cut in a way so I can fold it along the case edge. Holes are drilled for screws and the brass rod. This brass rod is used to hold a triangular wire that will clasp to the bottom part of the case. The rod is soldered to the brass plate but it also extends into the case wall to give it extra strength.

Then the parts are screwed into place and I filed the bottom rod part of the latch so the triangular piece will slide and hold easily. Very pleased with this result, it's not the cleanest looking thing but I like the handmade quality it has. Next post will show the end result of the watch case!

| |

| The finished latch on the case |

Subscribe to:

Posts (Atom)